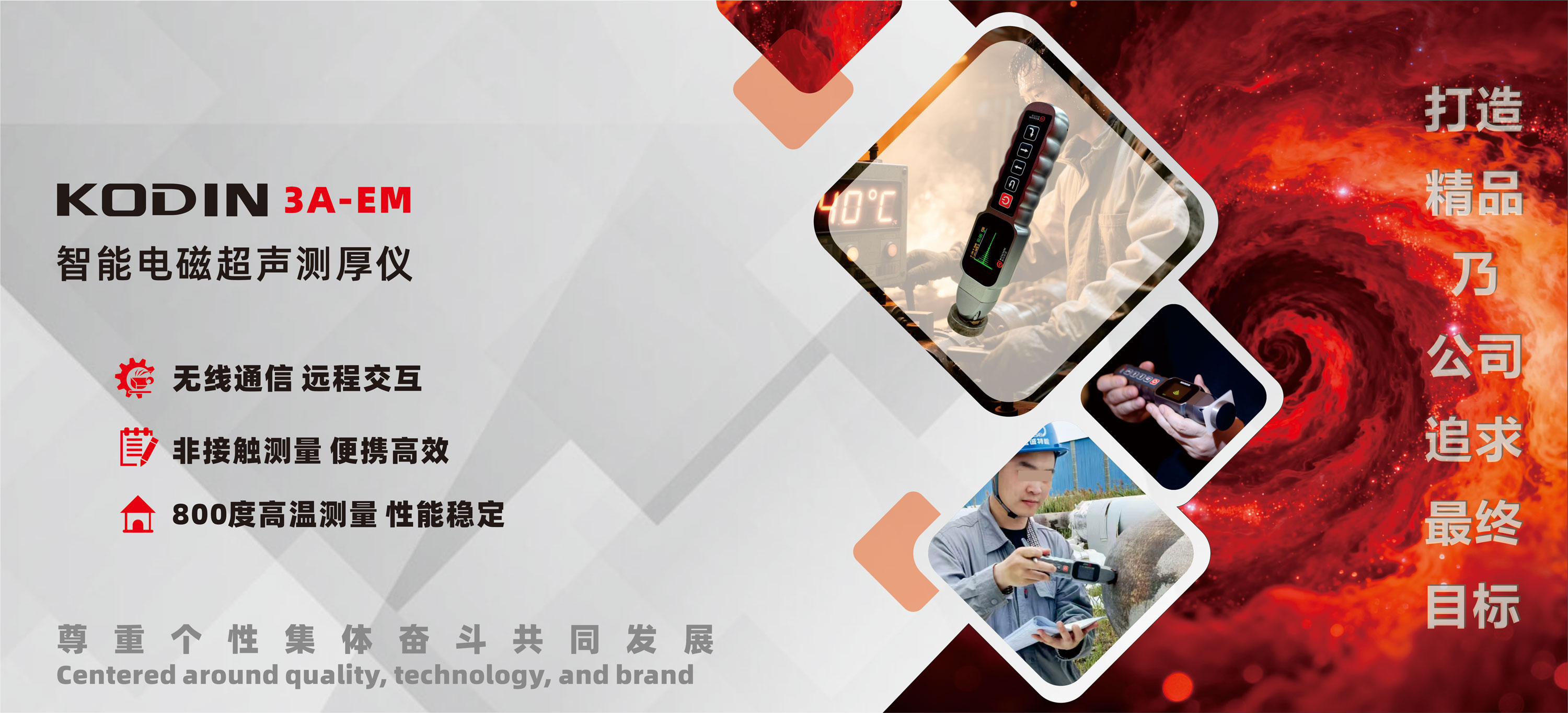

一、Instrument Overview:

KODIN 3A-MC series coating (plating) thickness gauge is an intelligent detection terminal built by Kedian Instruments based on Internet technology.

The KODIN 3A-MC fully split machine can be equipped with multiple different split probes on one host, and can measure coatings on multiple metals according to the different probe types.

二、Technical Specifications:

|

KODIN 3 Series Host Parameter Table |

||

|

Probe type |

F(Magnetism) |

N(Non-magnetic) |

|

Measuring principle |

Magnetic induction |

Eddy current |

|

Temperature compensation |

Phase Locked Loop (PLL) technology |

|

|

Measurement range |

Determined by the probe |

|

|

Display mode |

3.97-inch IPS high-definition color screen, 480 * 800 pixels |

|

|

Data interface |

Wireless transmission, USB transmission |

|

|

Operating system |

Android |

|

|

Calibration method |

Zero point calibration, system calibration, one point calibration |

|

|

Storage method |

Local eMMC storage, expandable TF card |

|

|

Data report |

Charts, images, and bar charts |

|

|

Display language |

Built in Chinese and English |

|

|

Measure speed |

You can choose between single measurement and continuous measurement |

|

|

Button light |

Backlight can be turned on and off |

|

|

Shutdown mode |

Physical button shutdown, software APP shutdown |

|

|

Protective design |

Dustproof, waterproof, and drop proof |

|

|

Usage environment |

Relative humidity: ≤ 90%; Temperature: -10 ℃~+40 ℃ |

|

|

Working hours |

≥7 hours (under minimum backlight brightness) |

|

|

Power supply |

Built in 3000mAh lithium-ion polymer battery |

|

|

Host size |

161mm(L)*73mm(W)*21mm(H) |

|

|

Total weight |

Approximately 253g (excluding probe) |

|

|

KODIN 3 series probe parameter table |

||||||

|

Probe model |

F/N0.5 |

F1.2 |

N1.2 |

F3 |

F5 |

F10 |

|

Measurement range |

0~0.5 |

0~1.25 |

0~1.25 |

0~3 |

0~5 |

0~10 |

|

|

|

|

|

|

|

|

|

The diameter of the largest small plane of the substrate |

10 |

15 |

18 |

18 |

18 |

22 |

|

Minimum curvature radius (concave) |

5 |

6 |

20 |

10 |

10 |

12 |

|

Minimum curvature radius (convex) |

1.5 |

2 |

5 |

5 |

5 |

5 |

|

The corresponding internal anti-corrosion probe can measure the minimum inner diameter of the pipeline |

45 |

50 |

240 |

80 |

80 |

110 |

|

Measurement accuracy (H is the thickness value)

|

±(1~3)%H±1μm 或H±2μm |

±(2~3)%H ±2μm |

±(2~4)%H ±2μm |

|||

|

Display precision |

0~99.9μm:0.1μm; 100~999μm:1μm; 1mm~10mm:0.01mm; <10mm:0.1mm |

|||||

|

Probe type |

F is a magnetic probe,N is a non-magnetic probe |

|||||

|

Critical thickness of matrix

|

N:0.5mm, F:1mm (F16: 5mm) |

|||||

|

Note: The default unit above is mm. |

||||||

三、Site of use:

四、Standard product packing list:

1. 1 main unit of coating thickness gauge

2. 1 set of data cable and charger

3. 1 SIM card ejector pin

4. 1 suitcase

5. 1 copy of user manual

6. 1 copy of warranty card and certificate of conformity

Optional accessories:

1. F0.5 probe

2. N0.5 probe

3. F1.2 probe

4. F3 probe

5. F5 probe

6. F10 probe

7. N1.2 probe

8. Internal anti-corrosion probe

9. (Fe/NFT) matrix

10. Sample piece

11. Screen protector

12. Wrist instrument clip

-

联系我们联系方式

| 上一条:None | 下一条:None |